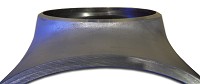

TEC-150 HD is the most powerful collaring machine for Schedule 40 pipes. You can make collars on tubes with wall thickness up to 0.5”. Maximum collar size is Ø 6” on 16” run tubes on Schedule 40 pipes on standard machine.

Entire process from pilot hole milling to a complete, beveled branch can be performed in a single workstation.

Technical Information

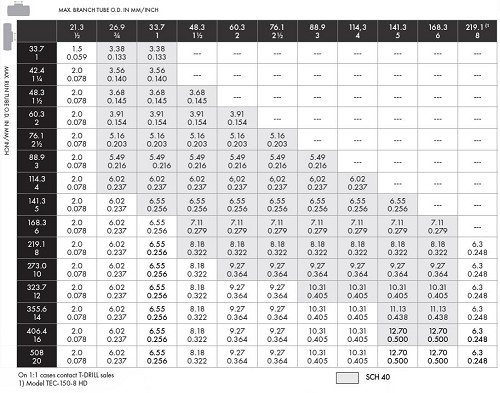

Capacity Chart for Maximum Run Tube Wall Thickness in mm and inch

TEC-150 SCH40 capacity table is only for the tool strength. It does not indicate anything about:

- collar quality

- wall thinning

- ability of material to withstand collaring

Note! In 1:1 cases, please contact T-DRILL Sales.

| TEC-150 HD |

Value |

| Operating voltage |

200-240 V / 50 Hz /60 Hz, 3-phase

400-480 V / 50 Hz /60 Hz, 3-phase |

| Collar diameter |

1/2" – 6’’ IPS

|

| Run tube diameter |

1" – 20’’ IPS |

| Max wall thickness |

See the capacity table |

| Spindle speed of the elliptic pilot hole cutter |

300 rpm |

| Min. pilot hole |

Ø0.433 |

| Max. pilot hole |

5.67'' x 4.80''

|

| Material suitable for collaring |

Iron, Stainless steel, Aluminium, Copper, Copper-Nickel |

| Compressed air supply |

87 psi

|

| Compressed air consumption |

13.2 gal/min |

| Connected power |

6 kW |

| Fuse sizes |

3 x 63 (max) |

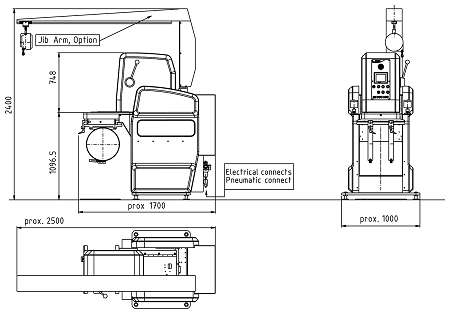

| Machine dimensions |

66.0'' x 38.6'' x 72.8'' (LxWxH) |

| Weight |

2200 lbs |

| Noise level |

Max. 85 dB |

Note! The values above are intended as a guide only.

Layout Drawing