The S-54 TBC (Tube Branching Center) is state-of-the-art automatic collaring system. It is used for the automatic production of manifolds providing the best use of floor space. This system with PC-controls is fully programmable with 2 axis motion controls. Optional bar code reader can be attached to control to read in the production data and select the right program.

The tube is fastened from its both ends to the Tube Branching Center. The suitable collaring program is selected from the PC controls and automatic cycle is started. TBC makes all the collars according to the selected program.

The Tube Branching Center consist of:

-

PC Based system with 2 axis motion controls

– Max tube length 59”

– Max tube length 118”

– Max tube length 236”

– Other table lengths available by request.

– Interactive, user friendly program for entering the collaring parameters.

– The collaring specifications can be stored on the hard drive

- Mist lubrication

-

S-54 Collaring unit

– Material: Copper and Aluminium

– Run tubes: ½” – 4⅛”

– Collaring range: ¼” – 2⅛”

– Material: Mild Steel and Stainless Steel

– Run tubes: ½” – 4⅛”

– Collaring range: ⅜” – 2⅛”

-

Clamping tools (for run tubes)

– Clamping tools are changed every time when Run tube diameter is changing.

– Including clamps, inserts for both tube ends

Technical information of S-54

| S-54 |

Collaring of Copper, Aluminium and Brass |

Collaring of Steel |

Collaring of Stainless Steel |

| Supply voltage |

200-240 V / 50 Hz /60 Hz, 3-phase

400-480 V / 50 Hz /60 Hz, 3-phase |

| Collaring range |

Ø6–54 mm / / 1⁄4” - 2 1⁄8” |

Ø10–54 mm / / 3⁄8” - 2 1⁄8” |

Ø10–54 mm / 3⁄8” - 2 1⁄8” |

| Diameter of run tube |

Ø8–108 mm / 5⁄16” - 4 1⁄8” |

Ø10–108 mm / 3⁄8” - 4 1⁄8” |

Ø10–108 mm / 3⁄8” - 4 1⁄8” |

| Spindle speed |

190–1000 rpm |

150–1050 rpm |

60–890 rpm |

| Rated power |

3 kW |

3 kW |

3 kW |

| Compressed air supply |

6 bar / 90 psi |

6 bar / 90 psi |

6 bar / 90 psi |

| Air consumption |

50 l/min / 1.765 ft³/min |

50 l/min / 1.765 ft³/min |

50 l/min / 1.765 ft³/min |

| Fuse |

3 x 16–63 (min – max) |

3 x 16–63 (min – max) |

3 x 16–63 (min – max) |

| Weight |

200 kg / 450 lbs |

200 kg / 450 lbs |

200 kg / 450 lbs |

| Dimensions of the unit |

930 x 280 x 1130 mm (DxWxH) |

930 x 280 x 1130 mm (DxWxH) |

930 x 280 x 1130 mm (DxWxH) |

| Noise level |

<70 dB(A) |

<70 dB(A) |

<70 dB(A) |

Note! The values above are intended as a guide only.

Technical information of Tube Branching Center TBC

| TBC |

Value |

| Diameter of the tube to be collared |

Ø⅞’’ - 4⅛’’ |

| Min. length of the tube to be collared |

3.35'' |

| Max length of the tube to be collared |

59'' 95'' or 118'' |

| Positioning tolerance between to consecutive collars |

+/- 0.008'' |

| Connected power |

7 kW |

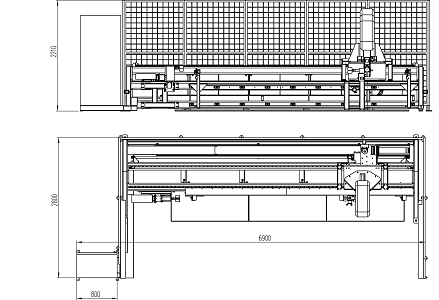

| Dimensions of the unit (AFT 2500) + S-54 |

394''x126''x87'' (LxWxH) |

| Weight (TBC 6000) |

6614 lbs |

Note! The values above are intended as a guide only.