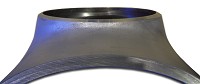

TEC-150-8 HD is the most powerful collaring machine for Schedule 40 pipes. You can make collars on run tubes up to 6″ with wall thickness up to 0.5″. The bigger branch size Ø 8” is limited to max. 0.248” wall thickness.

TEC-150 HD Collaring Station is now stronger and easier to handle than ever! Entire process from pilot hole milling to a complete, beveled branch can be performed in a single workstation.

Collars can be formed in most ductile materials, including stainless steel, carbon steel, copper/nickel, brass and aluminium. Depending on the material thickness and elongation, collars can be made for SCH 40 pipes according to the capability chart shown in Technical Information.

Technical Information

Capacity Chart for Maximum Run Tube Wall Thickness in mm and inch

TEC-150 SCH40 capacity table is only for the tool strength. It does not indicate anything about:

- collar quality

- wall thinning

- ability of material to withstand collaring

Note! In 1:1 cases, please contact T-DRILL Sales.

| TEC-150-8 HD |

Value |

| Operating voltage |

200-240 V / 50 Hz /60 Hz, 3-phase

400-480 V / 50 Hz /60 Hz, 3-phase |

| Collar diameter |

1/2"– 8’’

|

| Run tube diameter |

1’’ – 20’’ IPS |

| Max wall thickness |

See the capacity table |

| Spindle speed of the elliptic pilot hole cutter |

300 rpm |

| Min. pilot hole |

Ø0.43''

|

| Max. pilot hole |

5.67'' x 4.80''

|

| Material suitable for collaring |

Iron, Stainless steel, Aluminium, Copper, Copper-Nickel

|

| Compressed air supply |

87 psi |

| Compressed air consumption |

13.2 gal/min |

| Connected power |

6 kW |

| Fuse sizes |

3 x 63 (max) |

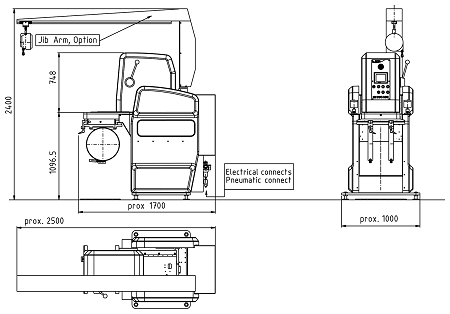

| Machine dimensions |

66.0'' x 38.6'' x 72.8'' (LxWxH)

|

| Weight |

2200 lbs |

| Noise level |

Max. 85 dB |

Note! The values above are intended as a guide only.

Layout Drawing