T-DRILL SEC-100 Collaring machine is a combination of two modular T-DRILL units integrated to the same frame. The pilot hole cutter, collaring process and trimming of the branch are done fully automatically without manual intervention.

The machine is specially designed for any manifold production in pipe fabrication applications. With SEC-100 it is possible to collar carbon steel, stainless steel, copper and other alloys as well as thin-walled Hastelloy pipes. In addition to manifold manufacturing, machine fits well for manufacturing level detection for liquids or similar application in the food, dairy, chemical or pharmaceutical industries.

An automatic work cycle with simple pre-set tools make the SEC-100 ideal for both high volume and short-run production.

Technical Information

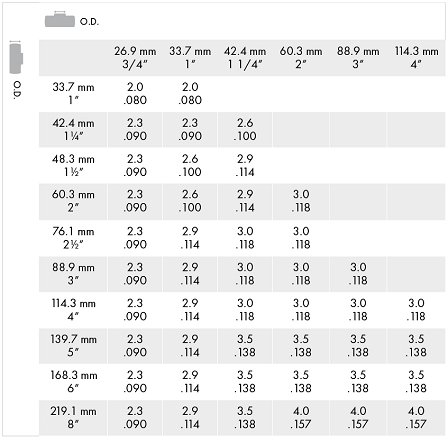

Capacity Chart for Maximum Run Tube Wall Thickness in mm and inch (run tube size on the left and branch size on the top)

| SEC-100 |

Value |

| Operating voltage |

200-240 V / 50 Hz /60 Hz, 3-phase

400-480 V / 50 Hz /60 Hz, 3-phase |

| Fuse |

Max 3 x 63A |

| Motor |

6,5 kW

|

| Air pressure |

36psi

|

| Air consumption |

7.9 gal/min, depending on the application

|

| Material to be collared |

Aluminium, Copper, Stainless steel, Steel |

| Collaring range |

ؽ’’ – 4’’ |

| Run tube diameters |

1’’ – 8’’ |

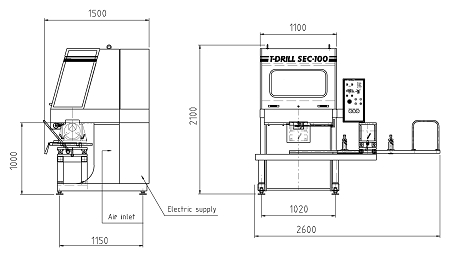

| Measures of the machine |

59.0’’x45.0’’x82.7’’ (LxWxH)

|

| Measures of the package |

118.1’’x74.8’’x86.6’’ (LxWxH)

|

| Net weight |

5732 lbs |

| Gross weight |

6613 lbs

|

| Colour |

RAL 7032/3003 |

Note! The values above are intended as a guide only.

Layout Drawing