The manual tube measuring table is used for controlled, accurate movements of the tube in both angle and axial directions. With the measuring table it is possible to specify accurately both the distance and the angle position between two collars or between the starting point and a collar.

There are two standard lengths available: 95” and 118”.

Tube Measuring Table 3000

- Manual measuring system for run-tube

- For diameters 1⅛ – 12” and lengths min. 3 x O.D. and max 95”

- Positioning tolerances:

length +/- 0.02” (machine); +/- 0.04” (tube)

angle +/- 0.5º (machine); +/- 1.0º (tube)

- Longitudinal and angle position can be seen from digital read-ou

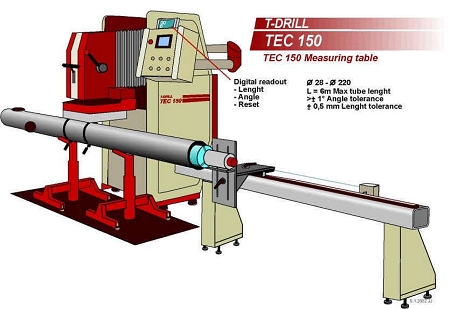

Tube Measuring Table 6000

- Manual measuring system for run-tube

- For diameters 1⅛ – 12” and lengths min. 3 x O.D. and max 118”

- Positioning tolerances:

length +/- 0.02” (machine); +/- 0.04” (tube)

angle +/- 0.5º (machine); +/- 1.0º (tube)

- Longitudinal and angle position can be seen from digital read-out

Technical Information

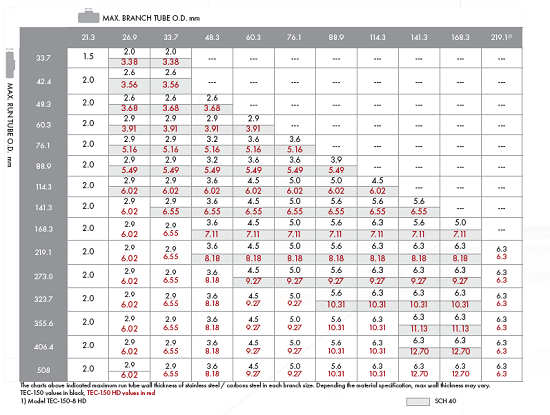

Capacity Chart for Maximum Run Tube Wall Thickness in mm (run tube size on the left and branch size on the top)

| TEC-150 |

Value |

| Material suitable for collaring |

Iron, Stainless steel, Aluminium, Copper, Copper-Nickel |

| Branch tube diameter |

½’’ – 6’’ IPS, option 8'' (pilot hole for 8'' collar is made separately) |

| Run tube diameter |

1’’ – 20’’ IPS (Min ¾’' with ball-pulling) |

| Max wall thickness |

See cabability chart |

| Mains supply |

200-240 V / 50 Hz /60 Hz, 3-phase

400-480 V / 50 Hz /60 Hz, 3-phase |

| Fuse size |

Max 3 x 63A |

| Connected power |

5 kW |

| Air pressure |

87 - 116 PSI |

| Air consumption |

13.2 gal/min

|

| Machine dimensions |

70.1'' x 49.2'' x 67.0'' (L x W x H)

|

| Package dimensions |

74.8'' x 53.1'' x 80.7'' (L x W x H)

|

| Net weight |

2200 lbs |

| Gross weight |

2866 lbs |

| Noise level |

Max 85 dB |

Note! The values above are intended as a guide only.

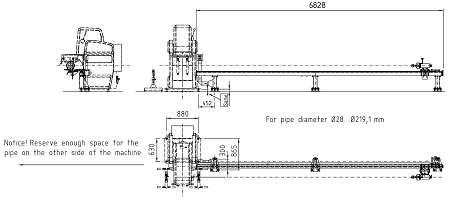

Layout Drawing

TEC-150 & positioning table for max 6000 mm long tubes