The collaring range of TEC-150-8 machine is even up to 8” on run pipes 1’’ – 20’’ IPS. The machine makes the elliptical pilot hole, forms a collar from the run pipe and trims the collar up to 6”. Pilot holes larger than for 6” collar are burned manually, e.g. with plasma cutter before placing the pipe to the machine.

There are the following modifications compared to the basic machine TEC-150:

- Larger trimming unit, jib arm and the positioning device for centering of the pilot hole/ run tube to the machine.

- The standard machine cannot be retrofitted to 8” capability.

Technical Information

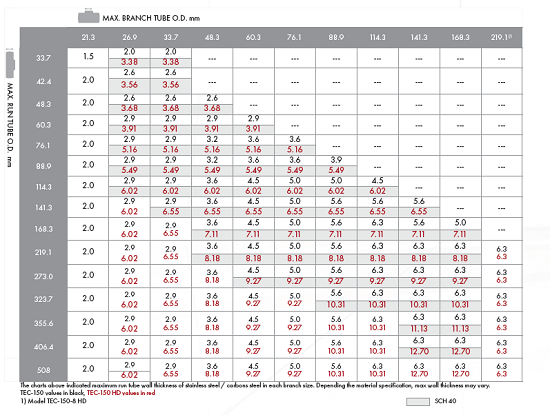

Capacity Chart for Maximum Run Tube Wall Thickness in mm

(run tube size on the left and branch size on the top)

| TEC-150-8 |

Value |

| Collaring diameter |

ؽ’’ – 8’’ (pilot hole for 8'' collar is

made separately) |

| Run tube diameter |

Ø 1’’ – 20’’ IPS |

| Tube material |

Carbon steel, Stainless steel, Copper-Nickel and Copper, Aluminium |

| Mains supply |

200-240 V/ 50/60 Hz, 3-phase

400-480 V/ 50/60 Hz, 3-phase |

| Rated power |

5 kW |

| Main fuse |

Max 3 x 63A |

| Net weight |

2200lbs |

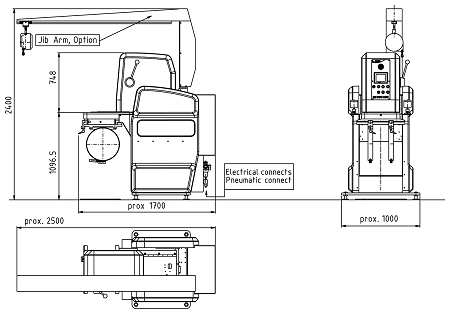

| Machine dimensions |

67''x 39'' x 71'' (LxWxH) |

Note! The values above are intended as a guide only.

Layout Drawing