SEC-100 TBC is an automatic collaring machine for making manifolds. It includes a feed table with either 1- or 2-axis control.

The tube is fastened from its both ends to the SEC-100 TBC. A suitable collaring program is selected from the PC controls and an automatic cycle is started. SEC-100 TBC makes all the collars according to the selected program.

Manual process:

- Preset the elliptical pilot hole parameters manually.

- Install the preadjusted collaring head and the clamps accoridng to the tube size.

- Set the axial tube stop.

- Mount the tube in the clamps.

- Push the start-button and the cycle will start.

Automatic cycle:

- The clamps close and the EC-100 mills the elliptical hole.

- When the hole is ready, the EC-100 unit retracts.

- The S-100 unit begins the collaring of the tube and the trimming of the collar.

- Finally the EC-100 returns to the milling position and the clamps open.

- On the TBC-model the unit is positioned according to the program and the cycle repeats.

Technical Information

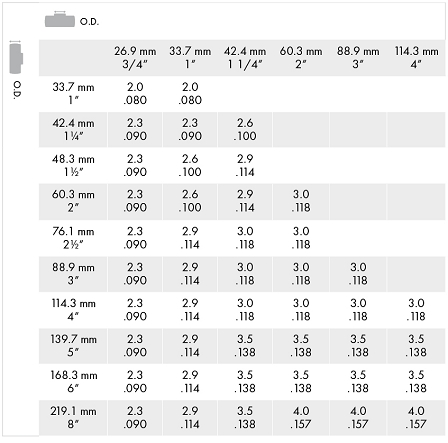

Capacity Chart for Maximum Run Tube Wall Thickness in mm and inch(run tube size on the left and branch size on the top)

| SEC-100 TBC 3000 |

Value |

| Operating voltage |

200-240 V / 50 Hz /60 Hz, 3-phase

400-480 V / 50 Hz /60 Hz, 3-phase

|

| Fuse |

Max 3 x 63A |

| Motor |

7 kW |

| Lubrication |

Automatic grease lubrication |

Process time

|

5–7 min

|

| Air pressure |

36psi

|

| Air consumption |

7.9 gal/min, depending on the application

|

| Material to be collared |

Aluminium, Copper, Stainless steel, Steel |

| Collaring range |

ؽ’’ – 4’’

|

| Run tube diameters |

Ø1’’ – 8’’ |

| Wall thickness |

See capability chart |

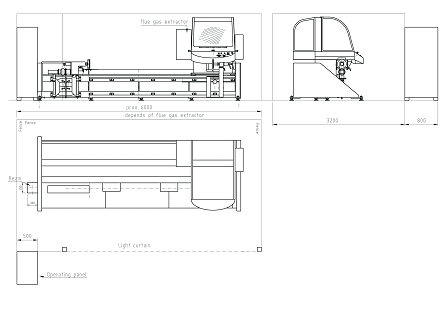

| Measures of the machine |

256''x126''x83''(LxWxH)

|

| Measures of the package |

264''x79''x87’’ (LxWxH)

|

| Net weight |

6945 lbs

|

| Gross weight |

8377 lbs

|

| Colour |

RAL 7032/3003 |

Note! The values above are intended as a guide only.

Layout Drawing