The T-110 Cu model is designed e.g. to the needs of heat exchanger manufacturers. It is a transportable collaring station for extruding branch outlets in copper tubes within range ⅞’’ – 10’’.

The system consist of a pilot hole cutter for making a round pilot hole, as well as the collaring tooling for diameter range ¾’’ – 4⅛ . Each collaring tool (collaring head) is adjustable within a certain range. Adjustment is made according to branch tube O.D.

The machine drills the pilot hole and formes a collar to the tube. The branch tube is connected to the run tube by brazed joint.

T-110Cu has the same working method as T-110, but due to the connection type, brazed joint, the trimming tool is not used.(See also Collaring machine T-110)

Technical information of T-110 Cu Collaring Machine

| T-110Cu |

Value |

| Collar diameter |

ؾ’’ - 4⅛

|

| Diameter of the run pipe |

Ø⅞’’ - 10’’ |

| Maximum wall thickness |

Max 0.21'' |

| Material to be formed |

Copper |

| Sound level |

Max 78 dB |

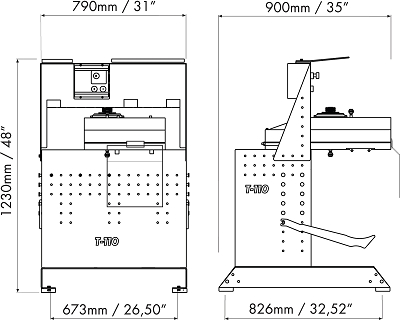

| Measures of the unit |

35.4''x31.1''x48.4'' (LxWxH) |

| Weight of the unit |

551 lbs |

| Operating voltage |

200-240 V / 50 Hz /60 Hz, 3-phase

400-480 V / 50 Hz /60 Hz, 3-phase |

| Fuses |

16A |

| Motor |

2,2 kW |

Note! The values above are intended as a guide only.