Transportable collaring machine is designed for welded tube connections for run pipes 1’’ – 12’’. The machine is 32’’ wide and the aim is to make it “easy to move” by manual- or motorized forklift.

The T-110 Collaring system consist of:

- T-110 collaring machine

- Pilot hole milling tool

- Collaring tools (with forming pins+pin holder according to collar diameters

- Trimming tool

- Clamping tools according to run pipe diameters

- Tool holders both side of the control panel.

The pilot hole tool, collaring tools and trimming tool are located at the tool holders both side of the control panel. The same tool holders can be used for tool setting. The buttons of the control panel are used to start and stop pilot hole milling, collaring and trimming cycles.

T-110 Working Cycle:

- The operator mounts the tube inside the opened clamps.

- The collar position is located and the clamps are closed by the operator.

- The pilot hole tooling is mounted to the T-110 collaring machine by the operator and the elliptical pilot hole is milled according to the preset settings.

- When the pilot hole is ready, the pilot hole tooling is replaced by the collaring tooling. Collar forming takes place.

- When the collar is ready, the collaring tooling is replaced by trimming tooling. Trimming of collar takes place.

- Finally trimming tool is removed from the T-110 collaring machine, clamps opened and the next collar can be positioned.

Technical information of T-110 Collaring Machine

| T-110 |

Value |

| Collar diameter |

ؽ’’ – 4’’ |

| Diameter of the run pipe |

Ø1’’ – 12’’ |

| Maximum wall thickness |

Steel 0.20''; Copper 0.20'' |

| Material to be formed |

Aluminium, Copper, Stainless Steel, Steel |

| Sound level |

Max. 78 dB |

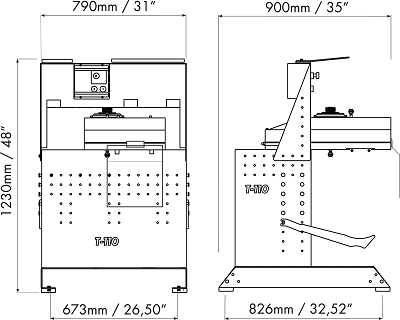

| Measures of the unit |

35.4''x31.1''x48.4'' (LxWxH) |

| Weight of the unit |

551 lbs |

| Operating voltage |

200-240 V / 50 Hz /60 Hz, 3-phase

400-480 V / 50 Hz /60 Hz, 3-phase |

| Fuses |

16 A |

| Motor |

2,2 kW |

Note! The values above are intended as a guide only.