T-65 SS Portable Heavy Duty Collaring Machine for Stainless Steel Pipes

Powerful T-DRILL Model T-65 SS is a fast, portable, easy-to-use tee forming machine for stainless steel tubes.

It is an ideal solution for making reducing tee joints of ½’’ – 1½’’ in main run tubes up to 4”. While giving you comparable quality to commercial tee fittings, your profits increases since T-65 eliminates two welded joints and the fitting cost. If tube polishing is required at the welding points, T-65 SS also reduces that, as well as any inspection costs. The branch pipe can be connected to a formed outlet either by orbital welding or by manual welding.

It is also possible to make tees in tubes from 4″ up to 8 2/3″ with optional special clamping system, which is shown at the photo below.

Technical Information

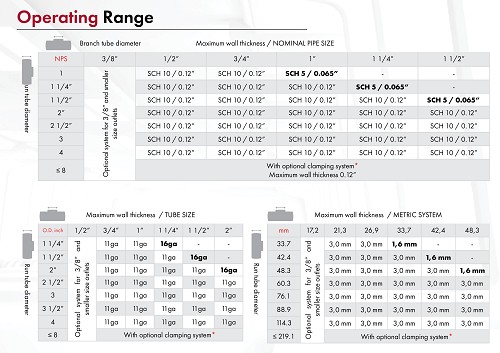

Capacity Chart for Maximum Run Tube Wall Thickness(run tube size on the left and branch size on the top)

| T-65 SS |

Value |

| Tee diameter |

½’’ - 1 1/4"’ NPS |

| Run tube diameter |

1'' - 4'' (8") NPS |

| Max. wall thickness |

See capability chart |

| Material |

Stainless steel, steel |

| Cycle time |

2–3 minutes |

| Spindle rotation speed |

0–500/50 rpm |

| Noice level |

82,5 dB (A) |

| Vibration |

less than 2,5 m/s2 |

| Dimensions of the unit |

22.4'' x 4.9'' x 7.1'' (LxDxH) |

| Weight of the unit |

11.9 lbs |

| Supply voltage |

230V / 50Hz

120V / 60 Hz

110V / 50 Hz |

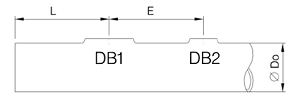

The distances between collars

Distance from the pipe end Lmin:

32 mm ≤ Do < 114,3 mm

Lmin = 50 mm

| Collar size |

E min |

| 21,3 mm |

63 mm |

| 26,9 mm |

66 mm |

| 33,7 mm |

69 mm |

| 42,4 mm |

73 mm |

| 48,3 mm |

76 mm |