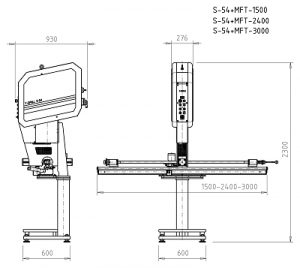

The basic Collaring Machine S-54 can be equipped with Manual Feed Table (MFT), which allows easy production of headers and manifolds.

The positioning is based on “pin-to-hole” method, which gives accurate positioning. The movement from one collar position to another is carried out manually by operator.

Standard MFT has three (3) positions where different collaring templates can be replaced. Operator can then quickly select any of these 3 templates to be used for collaring works. For every collar position a hole is being drilled to the template. This means, that for every tube that has different collar positions will need it’s own template.

Optionally, machine can be delivered with tube rotation system, where tube can be rotated by 15° increments using standard template. Other special radial templates are also available on request.

Standard Manual Feed Table lengths available:

- 59”

- 95”

- 118”

- Other table lengths available on request.

The tooling for holding the tube depends on the tube end; different tooling for open and closed tube end.

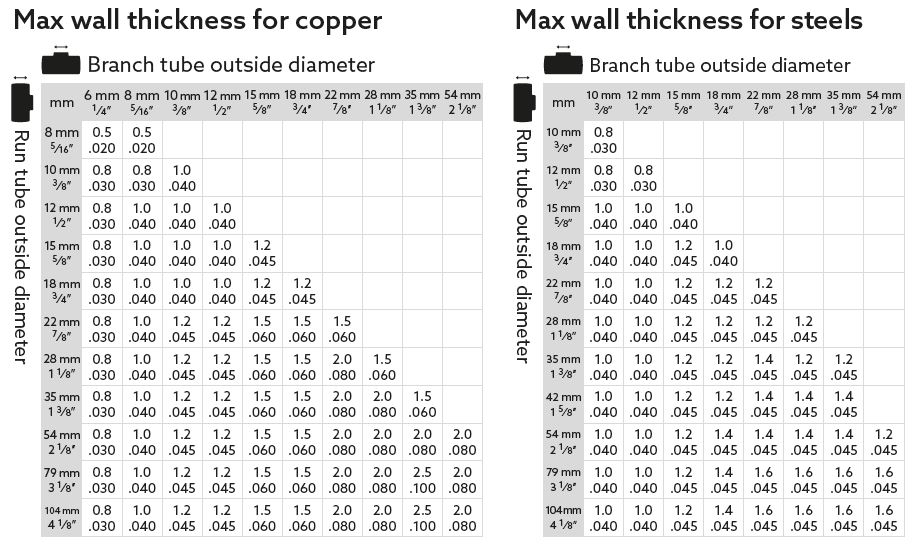

Capacity Chart – Maximum Run Tube Wall Thicknesses (run tube size on the left and branch size on the top)

Technical information of S-54

| S-54 |

Collaring of Copper, Aluminium and Brass |

Collaring of Steel |

Collaring of Stainless Steel |

| Supply voltage |

200-240 V / 50 Hz /60 Hz, 3-phase

400-480 V / 50 Hz /60 Hz, 3-phase |

| Collaring range |

Ø6–54 mm / / 1⁄4” - 2 1⁄8” |

Ø10–54 mm / / 3⁄8” - 2 1⁄8” |

Ø10–54 mm / 3⁄8” - 2 1⁄8” |

| Diameter of run tube |

Ø8–108 mm / 5⁄16” - 4 1⁄8” |

Ø10–108 mm / 3⁄8” - 4 1⁄8” |

Ø10–108 mm / 3⁄8” - 4 1⁄8” |

| Spindle speed |

190–1000 rpm |

150–1050 rpm |

60–890 rpm |

| Rated power |

3 kW |

3 kW |

3 kW |

| Compressed air supply |

6 bar / 90 psi |

6 bar / 90 psi |

6 bar / 90 psi |

| Air consumption |

50 l/min / 1.765 ft³/min |

50 l/min / 1.765 ft³/min |

50 l/min / 1.765 ft³/min |

| Fuse |

3 x 16–63 (min – max) |

3 x 16–63 (min – max) |

3 x 16–63 (min – max) |

| Weight |

200 kg / 450 lbs |

200 kg / 450 lbs |

200 kg / 450 lbs |

| Dimensions of the unit |

930 x 280 x 1130 mm (DxWxH) |

930 x 280 x 1130 mm (DxWxH) |

930 x 280 x 1130 mm (DxWxH) |

| Noise level |

<70 dB(A) |

<70 dB(A) |

<70 dB(A) |

Note! The values above are intended as a guide only.

Technical specification of MFT

| MFT |

Value |

| Diameter of the tube to be collared |

Ø 5/16 - 4⅛" |

| Min. length of the tube to be collared |

2'' |

| Max length of the tube to be collared |

59'', 95'', 118'' or 236" |

| Positioning tolerance between to consecutive collars |

+/- 0.01'' or better |

| Air consumption |

14,8 gal/min |

| Dimensions of the unit (MFT 2500) + S-54 |

37''x256''x91'' (LxWxH) |

| Weight (MFT 2500) |

992 lbs |

Note! The values above are intended as a guide only.

Manual Feed Table specification

| Type |

MFT 1500 |

MFT 2400 |

MFT 3000 |

| Length |

84.2'' |

84.2'' |

84.2'' |

| Depth |

14.7'' |

14.7'' |

14.7'' |

| Height |

8.9'' |

8.9'' |

8.9'' |

| Weight |

161 lbs |

246 lbs |

267 lbs |

| Workpiece max length |

59'' |

95'' |

118'' |

Tooling for holding the tube (different for open tube ends and closed tube ends):

– 1 set of tube adapters /O.D. (Manufactured for specific tube O.D. and wall thickness. On order tube O.D. diameters and wall thickness have to be specified)

– 1 set of tube supports / O.D