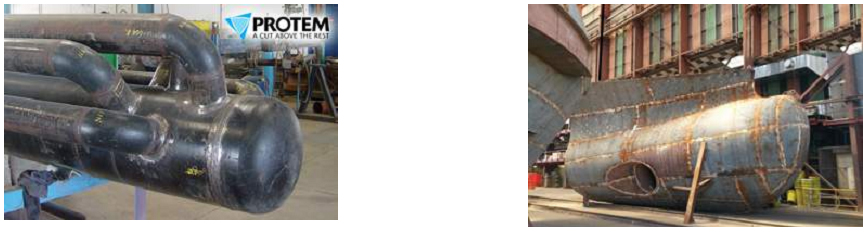

The US80 portable tube and pipe heavy duty beveler combines durability, reliability, effiency and versatility in one machine, providing a safe and easy use for all operators. The standard tool-plate will accept multiple tool bits, allowing up to four simultaneous machining operations. Such operations may include 30°, 37°30, 45° bevels with or without land, J-bevels, compound bevels, facing, counterboring operations, etc.

The US80 heavy duty beveler will perform repeatable high quality weld preparations on all types of materials including mild steel, chrome, stainless steel, duplex, super duplex, copper-nickel alloy steel, inconel, P91, aluminium, copper and exotic alloys. It can be either pneumatically, electrically or hydraulically driven. The tool bits can be changed and adjusted very quickly. Carbide tool inserts may also be used.

Pneumatically driven machines have to be used with a lubricating fiter. Recommended option: regulation valve

Advantages:

- Transportable

- Powerful Machining Equipment

- Easy and Safe use for the Operators

- No Heat Affcted Zone

- High Accuracy

- Fast and easy mounting

- The tool bits can be changed and adjusted very quickly

- Adapted for works in tight spaces

- The machine can be used in all positions: vertical, horizontal, over head

- Versatile Cutting Head: the tool-holder plate can accept up to 4 tool bits for simultaneous machining operations (land, bevel, counterboring, j prep)

- Smooth and Burr-Free Surface Finish

- No vibration during the machining process

| ORDER NR. |

DESCRIPTION |

| US80-1000 |

Heavy Duty Pipe Facing Machine with dual pneumatic drive, for Ø 3.149“ - 13.976“ (80mm - 355mm) |

| US80-1002 |

Heavy Duty Pipe Facing Machine with pneumatic drive, for Ø3.149“ - 13.976“ (80mm - 355mm) |

| US80-1020 |

Heavy Duty Pipe Facing Machine with electric drive 220V, for Ø3.149“ - 13.976“ (80mm - 355mm) |

| US80-1060 |

Heavy Duty Pipe Facing Machine with dual hydraulic drive and regulation valve, for Ø 3.149“ - 13.976“ (80mm - 355mm) |

| US80-1062 |

Heavy Duty Pipe Facing Machine with hydraulic drive, for Ø 3.149“ - 13.976“ (80mm - 355mm) |

| US80-1064 |

Heavy Duty Pipe Facing Machine with single hydraulic drive and regulation valve, for Ø 3.149“ - 13.976“ (80mm - 355mm) |

| US80-1066 |

Heavy Duty Pipe Facing Machine with single hydraulic drive, for Ø 3.149“ - 13.976“ (80mm - 355mm) |

| US80-1080 |

Heavy Duty Pipe Facing Machine with brushless electric drive --Three-Phase Motorization-- Please indicate the required voltage and frequency for your application. For Ø 3.149“ - 13.976“ (80mm - 355mm) |

| US80DSB-1000 |

Heavy Duty Pipe Facing Machine with dual pneumatic drive, regulation valve and dual bearing (higher accuracy) for Ø 3.149“ - 13.976“ (80mm - 355mm) |

| US80DSB-1060 |

Heavy Duty Pipe Facing Machine with dual hydraulic drive, regulation valve and dual bearing (higher accuracy) for Ø 3.149“ - 13.976“ (80mm - 355mm) |

Applications:

Use On-Site or in Workshop: