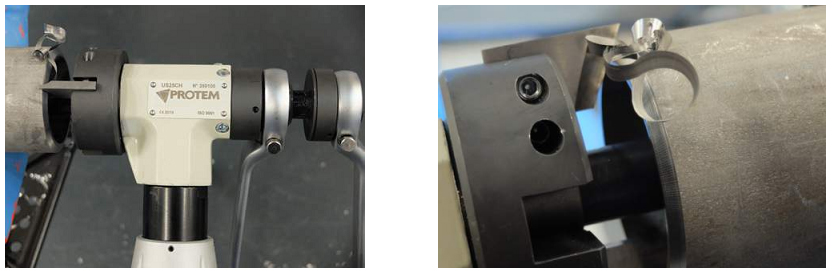

The PROTEM US25CH will perform repeatable high quality weld end preparations on virtually all materials including mild, chrome, stainless steel, duplex, super duplex, copper-nickel alloy steel, inconel, P91, aluminium, copper, exotic alloys, etc...

The ID mount and portable US25CH is adapted for the maintenance and repair of Boiler and Heat Exchanger Tubes. It features a modifid torque, the tool-holder plate features 2 grooves to mount standard HSS tool bits, 2 grooves with locking wedges to mount insert holders, the addition of a double-lip seal to prevent chips from entering into the machine when working on ceiling mounted panels/components, the addition of a sintered guide ring to replace the needle bearing, the addition of a bushing (protection against chips) , a specifi longer clamping shaft (specifially designed to clamp after flred parts) basic blades with a 8° angle

Pneumatically driven machines have to be used with a lubricating fiter. Recommended option: regulation valve

Advantages:

- Portable

- Powerful Machining Equipment

- Easy and Safe use for the Operators

- No Heat Affcted Zone

- High Accuracy

- Fast and easy mounting

- The tool bits can be changed and adjusted very quickly

- Adapted for works in tight spaces

- The machine can be used in all positions: vertical, horizontal, over head

- Versatile Cutting Head: the tool-holder plate can accept up to 4 tool bits for simultaneous machining operations (land, bevel, counterboring, j prep)

- Smooth and Burr-Free Surface Finish

- No vibration during the machining process

| ORDER NR. |

DESCRIPTION |

| US25CH-1010 |

Boiler Maintenance Unit US25CH, fited with tool-holder plate Ø 2.362“ (60mm) and pneumatic drive MO10. |

| US25CH-1012 |

Boiler Maintenance Unit US25CH, fited with tool-holder plate Ø 3.543“ (90mm) and pneumatic drive MO10. |

| US25CH-1014 |

Boiler Maintenance Unit US25CH, fited with tool-holder plate Ø 2.952“ (75mm) and pneumatic drive MO10. |

| US25CH-1016 |

Boiler Maintenance Unit US25CH, fited with tool-holder plate Ø 4.724“ (120mm)and pneumatic drive MO10 |

| US25CH-1032 |

Boiler Maintenance Unit US25CH, fited with tool-holder plate Ø 3.543“ (90mm) and electric drive 220V |

| US25CH-1052 |

Boiler Maintenance Unit US25CH, fited with tool-holder plate Ø 3.543“ (90mm) and electric drive 110V |

Applications:

Use On-Site or in Workshop: