The Ultimate Split 6 orbital cutting machine is used for cutting tubes made of virtually all materials having diameters ranging from 1/2“ (12.7 mm) to 6“ (168 mm) and wallthicknesses ranging from 0.04“ (1 mm) to 0.59“ (15 mm).

It enables the cutting of pipes without any deformation thanks to its concentric clamping system. The cut is absolutely perpendicular and burr-free. The adjustment to the different diameters is very simple and fast.

The Ultimate Split 6 is the orbital cutting saw you need for all your welding preparation works on-site or in the workshop.

Various motorization options are available: Electric or pneumatic

The orbital cutting process used for the US6 provides a lot of advantages:

- Perpendicular cut

- Automatic centering onto the pipe

- Perfect concentric clamping

- Burr-free cut

- No Vibration

- No heat-affcted zone

- Excellent preparation for mechanised welding processes

- Rigidity, ergonomic design, flexibility, reliability

- Suitable for all types of steel: mild steel, stainless steel, duplex, super duplex, inconel, hastelloy, aluminium, copper, titanium

ULTIMASTER orbital pipe cutting units are the ideal solution for your on-site jobs. These machines are also perfectly suited for prefabrication workplaces and they can be used under severe conditions (extreme temperatures, high humidity, ionizing radiations)

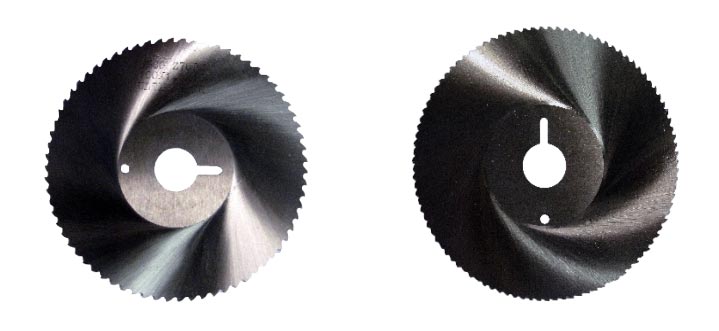

CUTTING SAW BLADES

Diffrent saw blades can be used, depending on the pipe thickness to be cut. The diameter of the orbital cutting saw blades is constantly 100 mm (3. 94“) .

Specific coating TIALN available on order.

| Order Ref. |

Diameter |

Number / Teeth |

Pipe Thickness |

Blade Thickness |

| US-LC-1426 |

100 mm (3.94“) |

100 |

0.5 - 1.5 mm (0.02“ - 0.06“) |

1,6 mm (0.63“) |

| US-LC-1430 |

100 mm (3.94“) |

70 |

1 - 3 mm (0.04“ - 0.12“) |

1,6 mm (0.63“) |

| US-LC-1427 |

100 mm (3.94“) |

64 |

3 - 7 mm (0.12“ - 0.28“) |

2 mm (0.08“) |

| US-LC-1428 |

100 mm (3.94“) |

44 |

7 - 12 mm (0.28“ - 0.47“) |

2 mm (0.08“) |

| US-LC-1429 |

100 mm (3.94“) |

34 |

12 - 15 mm (0.47“ - 0.59“) |

2,5 mm (0.10“) |